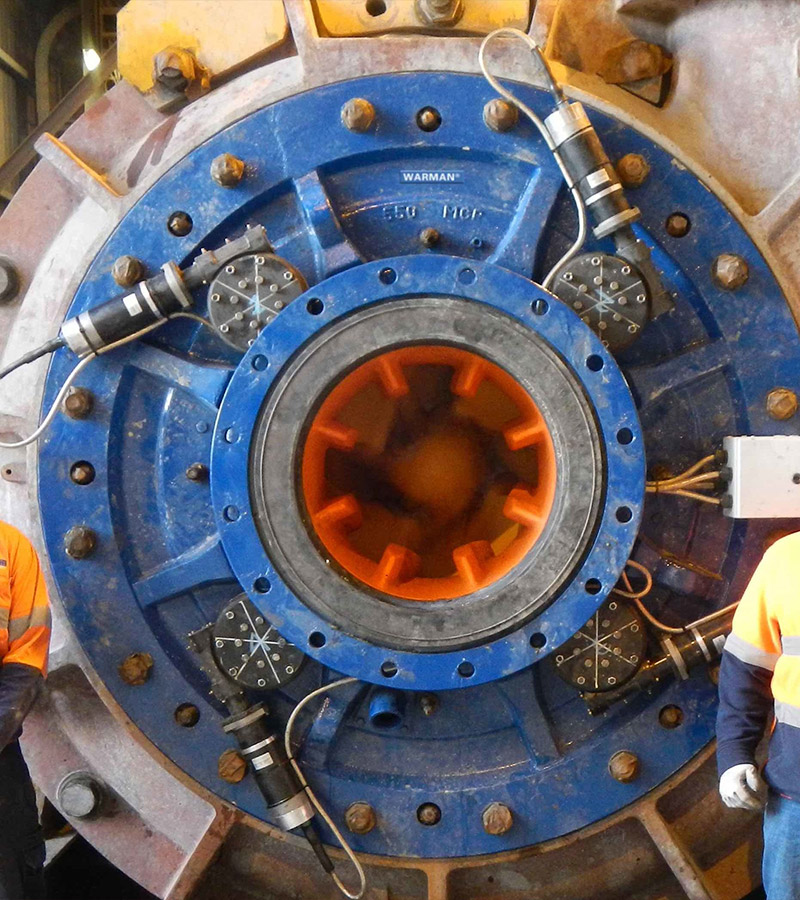

Weir Minerals Automated Foundry Upgrade

SCOPE / INVOLVEMENT

In a groundbreaking collaboration, CLR embarked on a pioneering project to construct a state-of-the-art automated foundry system for Weir Minerals’ centrifugal pump manufacturing plant. Partnering with DKE, CLR’s expertise converged to create a transformative landscape that would redefine manufacturing processes.

The project’s foundation was laid with the construction of intricate support structures – a masterful dance of engineering precision. Working in tandem, DKE and CLR meticulously crafted these foundational elements, ensuring they were primed for seamless installation. The culmination of this phase witnessed the arrival of these structures on-site, where CLR orchestrated a carefully choreographed process of craning in substantial steel beams, eventually piecing together the framework according to the exact specifications detailed in the client’s drawings.

With the support structures securely in place, CLR’s ingenuity took center stage once again. A symphony of chutes and shaker tables was meticulously orchestrated, harmoniously fitting into the assembled framework. Every installation was a testament to CLR’s commitment to precision, adhering closely to the client’s specifications and engineered drawings.

This collaborative effort stands as a beacon of innovation and technical mastery. The automated foundry system, a testament to CLR and DKE’s prowess, represents more than machinery – it signifies a bold step towards efficiency, quality, and manufacturing excellence. This project encapsulates the remarkable synergy of engineering expertise and vision, forging a path that will redefine manufacturing for years to come.

PROJECT

Weir Minerals Automated Foundry

CLIENT

Dark Night engineering